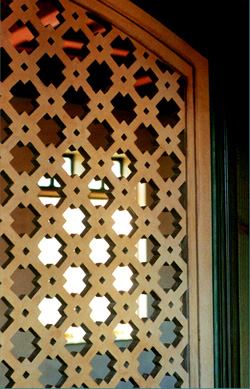

“Laciness” and “delicacy” may not be the words that pop into your head when you think of concrete. But Berkeley, Calif., architect/engineer/builder Gary Black achieves just those qualities in the decorative concrete screens he has fabricated for a number of residential and commercial projects. To produce the complex forms involved, he cuts the void shapes from rigid foam board with a hot wire and glues the pieces to a sheet of MDF. “What ends up being the hole was once a piece of Styrofoam,” he says. After waxing the forms, Black pours one of several concrete mixes. For interior screens, he uses Tufstone, a gypsum-based cement. For exterior locations, he has used both Garden Cast, a fast-setting cement used for garden ornaments, and self-compacting concrete. “It’s labor intensive, and you can end up with a pile of nothing really easily,” cautions Black, who charged $1,500 for a recent 3-foot-by-3-foot panel. But the results, as in this screen he fabricated for a custom home in Sonoma, Calif., show concrete in an entirely new light.