IS THERE SUCH THING AS A COMPLETELY original, undiscovered niche in today’s housing market? Robert Luntz, a partner with Resolution: 4 Architecture, a New York–based architectural firm, believes he has discovered just such a prize.

“We think there’s a segment of the population that’s underserved,” Luntz says. “Where are all these people who live in cool lofts and spaces in the city supposed to go when they move to the country? They certainly don’t want to go live in a colonial-style house.”

But the obstacle to more people moving into hip, modernistic homes isn’t a matter of not enough demand, he insists. It’s a matter of cost.

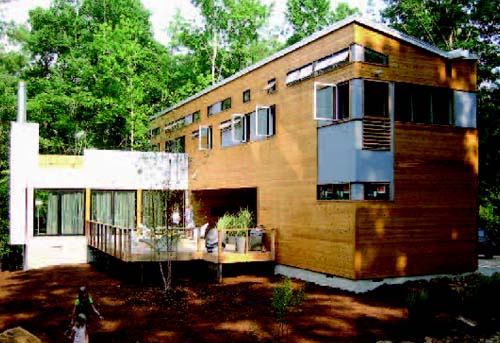

“Basically, in our area, a modern house is $350 to $500 a foot,” Luntz explains. “We’ve been practicing for 15 years and have tried to come up with a method to do modern work for a relatively affordable price. That led us to modular.”

Assembling A Workforce The utility of modular construction had always appealed to Luntz, he says, just not the traditional floor plans. “There’s a whole industry that builds modular homes,” he notes. “They build on time, in a controlled atmosphere, and create a quality product.

“Our work in Manhattan required us to work in a lot of lofts 15 feet wide by 50 feet long, so we began to put together a ‘typology’ of designs,” he adds. This library of geometric “modules” makes it possible for the architects to communicate their designs to established modular manufacturers such as Apex Homes of Pennsylvania. As a result, they have been able to build their prefab modern designs for about one-fourth the cost of a site-built equivalent home.

Where do builders and tradespeople fit into the picture? At this point, Luntz says, the architects have been selling the idea to promising contractors.

“We’ve identified several prototypical types of builders, [and we’re] telling them about us,” Luntz says. “First, we’re calling modular builders. Then, we’re talking to custom builders who focus on renovations and additions. They understand the fact that once the home arrives, it has to all be put together and the trim work has to be done. Then there’s the standard one-off custom builder. Maybe he’s having trouble with labor and weather and taking a year to finish one project, and he’d like to do more work in the same time.”

Who Will Buy? But is the demand for these stylish boxes real? Do the math, says Luntz. His firm’s Web site gets 15,000 to 20,000 hits a day, with about 15 phone call inquiries interested in modernist modulars.

Learn more about markets featured in this article: New York, NY.