What’s imaginable becomes doable when manufacturers and designers collaborate at a higher level. That collaborative effort can lead to manufacturing the walls of a home, to manufacturing every piece of a home. Either way, there are a whole host of benefits, and at the top of the list are efficiency and sustainability.

During the Builder Sustainability Forum, John Barrows, owner of P3 Builder Group, Inc., spoke as a true, experienced builder. His career has been founded on building custom homes from sticks. He knows the process in and out, as thousands of other builders nationwide. The difference between Barrows and then rest of them is that he was willing to try something new. When he did, he found that he was able to benefit because building with sticks in the field presents more moving parts with less control than a factory built panel.

In a short time, Barrows has become a strong believer in the benefits that panelization brings. Panelization also bridges the comfort gap. With panelization, which is building the walls with framing, windows, wiring and insulation in the factory and then erecting them on site, some of the main elements are delivered intact so he can be more comfortable with the project.

Plus, with the factory setting, there is a higher level of quality control, which is tied in with fewer resources and better efficiencies. There are some challenges that he’s working on narrowing down, including flexibility and restrictions on getting the walls down the road to the job site.

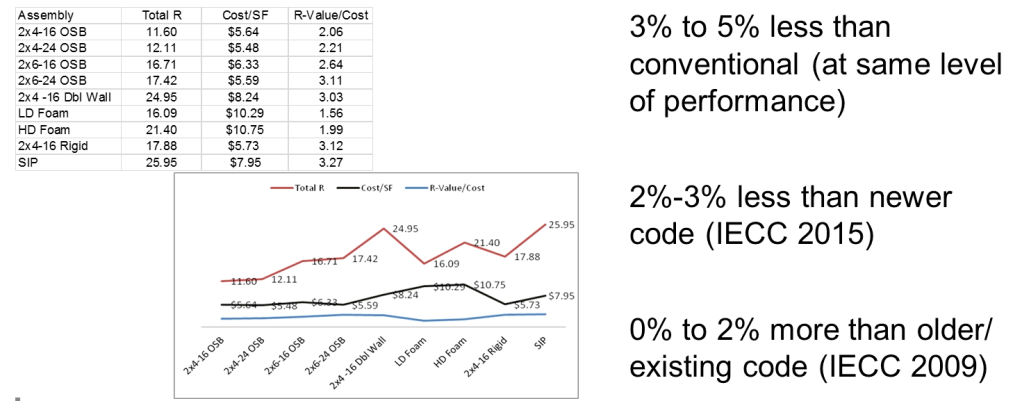

Depending on air exchange requirements, panelization can be 5% less than conventional building.

And, although these factors are a strong influencer for converting to panelization, Barrows has found that in order to reach code for the market he builds in, which requires three air changes per hour, there is a lower cost in using panels than there is with basic stick built. With the old code, the panel system was more expensive, but now it is outperforming in terms of efficiency and cost.

Other builders are turning to an even more advanced process that Joseph Wheeler, co-director at the Center for Design Research, Virginia Polytechnic Institute and State University explains. This concept, explored through the Greenbuild KB Home ProjeKt, puts an entire room into the factory with the only limitation as the transportation to the job site.

Wheeler has been creating concepts and even took out a loan to spearhead construction of a home completely from cartridges to verify the benefits. That 2,200-square-foot home was pieced together with 12. In one day, all the cartridges were lifted into place and it was drywalled in in 3 days.

The cartridges Wheeler uses are packaged to have only one avenue for all the electric, which is a new efficiency equation to building a home. In the future, he contends that a cartridge will be able to be unplugged from a home, renovated and then plugged back in.

Wheeler also is exploring the future of smart homes based on the cartridge design and integrating all aspects of technology into the concept. The smart kitchen will offer hands-free water operation, voice commands for temperature, integrated sensors, social tables with multi-touch displays and digital interfaces so the home owner can research recipes and transfer to a virtual window. He even envisions the windows transforming into a Skype call with grandma so she can walk her grandchildren through cooking her famous casserole. Induction cooking also has the capacity to transform the kitchen by being integrated under counter tops, freeing up the space when it isn’t being used for cooking.

With these technologies and the benefits behind them, the future is limitless. Now builders just need to feel comfortable using them.