A five-story multifamily building in San Jose, Calif., pushes residential modular building to the extreme, and now it has won an award for its superior design.

The 444-unit luxury Domain Apartments are the largest in the country to be constructed of pre-manufactured modular units placed on a post-tensioned parking podium. The development, which opened in November 2013, recently was named best-in-show in the Modular Building Institute’s 2015 Awards of Distinction competition.

Guerdon Modular Buildings

Domain Apartments' 485 modular units include high-end upgrades such as 9-foot ceilings, granite countertops, stainless steel appliances, and washers and dryers.

The structure’s 485 modular units were built at Guerdon Modular Buildings’ manufacturing facility in Boise, Idaho, including all finishes and high-end upgrades such as 9-foot ceilings, granite countertops, stainless steel appliances, and washers and dryers. The units were trucked to the construction site and set in place using one of the largest production cranes in the country, a LR 1400/2 with a 390-foot-tall boom. The only on-site construction required was exterior shear bracing and siding, says Curtis Fletcher, Guerdon’s regional business development manager.

Using modules and panels to create housing often shaves months off the time it takes to build a multifamily development. That means the project’s construction financing can be retired sooner and the property can start earning income by renting or selling its units, says Lad Dawson, Guerdon CEO.

Curtis Fletcher

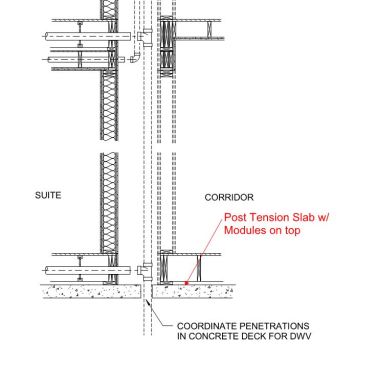

A post tension slab is commonplace for construction in dense urban areas where buildings need either parking or commercial space below the residential areas. Post tensioning refers to cable tendons that are placed in a relatively thin section of concrete. After the concrete cures, the cables are tensioned causing the concrete slab to slightly bow upward in the middle making it stronger and able to hold more weight in a uniform manner. This also requires fewer and more evenly spaced columns, says Curtis Fletcher, Guerdon’s regional business development manager.

Modular and panelized construction can also save money because of the cheaper labor and materials in factories far away from expensive urban markets.

The modular approach was beneficial for the project’s developer, Equity Residential, given the tight time constraints created by the rapidly increasing demand for multifamily housing in their market, says Dawson. “They estimated that our modular technology allowed the complex to go to market about nine months sooner and reach full lease stabilization one year earlier than if it had been site-built, while improving quality.”