It’s taken eight years, but it looks now like Michael Niemann’s HercuTech is on the verge of getting to what he’s doggedly pursued that whole time.

A break-out year for a product and process that could change, in pretty short order, a lot of the conversation we’ve been having about home builders and economic productivity.

HercuTech, mind you, is not a household name in building products. So, although Michael Niemann’s been pushing his firm’s game-changer product–HercuWall®, an insulated concrete panel precisely pre-cut offsite for rapid assembly on site–that whole time, one can still only say it’s “on the verge” of something much bigger.

“You can say one thing about me,” said Neimann over dinner on the evening after we’d done the frame walk at the Meritage reNEWable Living Home in Orlando, Fla. “I’m persistent.”

The product–actually a misnomer for a combination of products and a re-mapping of an entire set of design, engineering, and construction workflows–took a technology that was strong and performed well–insulated concrete form-based block walls–across a critically important dividing line.

ICFs, for all the good they offer in terms of above- and below-grade durability, are not economically viable as a widely used building technology, particularly in single-family. They don’t scale. Placing polystyrene blocks on-site, pouring the concrete with reinforcing bars to gain ICF benefits takes more time, not less, more skilled labor, not less, and more money, not less.

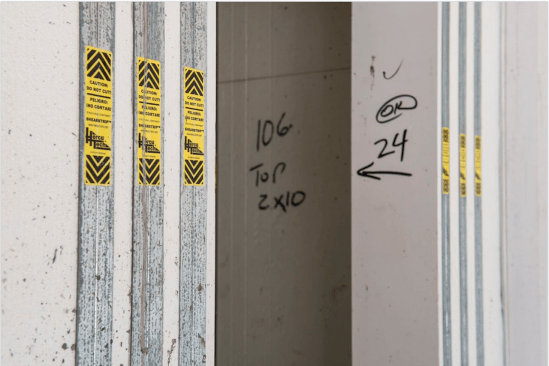

Meritage Homes

The panelized wall process reduced the construction of the first floor from two weeks to one day.

Niemann’s ICP HercuWall® system is all about scalability, which is one reason Meritgage vp of Environmental Affairs CR Herro fell in love with HercuWall® the moment he saw it at Greenbuild in 2009, when HercuTech, in cooperation with the Salt River Materials Group (SRMG), built a tour home for the conference that showcased the system.

Niemann explains that the reason ICPs can scale and ICFs can not is simple to understand but very hard to do.

“We had to get rid of the rebar,” he says. HercuWall® doesn’t have its concrete support derive from steel reinforcing bar running through the panels. Instead, a product Niemann invented called ShearStrip® provides the reinforcing.

As the HercuTech website describes:

“HercuWall® panels contain voids that are filled with concrete. These voids determine the shape of the concrete within the HercuWall® system which is analogous to a concrete stud wall. There are vertical concrete studs placed on regular 12” centers, a continuous concrete base, and a continuous concrete bond beam at the top of the wall. Each concrete stud attaches to a ShearStrip™ which are juxtaposed facing to the interior at one stud and the adjacent studs facing the exterior.”

Photo by John Unrue

Now, the ShearStrip® technology didn’t pop out of Niemann’s mind fully-formed. He recalls an early-development program where longtime partner LafargeHolcim wanted to beta test some of Neimann’s products before making a significant investment and endorsement of the HercuWall® line. The challenge with the concrete is that it needs two essential properties to work in the ICP application: flow and strength. Getting them in balance is tricky, because one property tends to conflict with the other.

“We poured the concrete into the forms and the forms exploded,” Niemann told us. “The Lafarge people were devastated and thought the experiment was a total failure. But, I came back to them and, said, ‘Look, no it was not a failure. We can fix what went wrong. We just have to get the reinforcing right.'”

Now Lafarge, North America’s No. 3 concrete producer, have become partners in marketing HercuWall® to residential builders throughout North America.

“What did I tell you, persistence!” said Niemann.

Niemann comes by this trait honestly. As a young, young kid growing up in Wisconsin Rapids, Wisc., he loved hanging out, playing on the floor at his dad’s company.

The office, in this case, was the floor of a bygone kitchen and camping appliance manufacturing plant, a large company called Preway, whose heyday was the mid-1950s through the mid-’70s.

“My school science projects tended to be on the very geeky side,” said Niemann.

Now, the need for Niemann’s key trait is not a one-and-done now that he’s got a marketing partnership with LaFarge and a strong endorsement from the folks at Meritage.

It’s a known fact that, as an industry, home building tends to be averse to innovation, and the HercuWall system–as well as plans for a pre-fabricated stucco cladding on the panels’ exteriors–may strike builders the way his science projects struck his peers when he brought them into school.

What’s more, building envelope innovation interacts and interoperates with window and door openings. Given that the walls come to the site pre-cut to precise specifications by CNC machines, builders on site noted that this amount of accuracy in size, straightness, and plumbness can almost turn out to be a challenge for some of the manufacturers, since they deal almost invariably with inaccuracies that require added work around the window bucks.

Not having to do those on-site adjustments to correct for little margins of error is an adjustment in itself.

As BUILDER contributor Sam Rashkin has noted ICP “value propositions that can not be matched by wood framing:”

Superior Construction:

- Much faster construction time

- Less tools for assembly

- Substantially reduced enclosure subcontactor work (e.g., framing, insulation, air sealing)

- Superior moisture protection

- Substantially less waste

- Superior quality fit, finish, and trim

- Smaller heating and cooling systems due to substantially reduced loads and outstanding control of mean radiant temperatures

Superior Performance:

- Superior strength

- Superior wind resistance

- Superior fire resistance

- Superior quiet

- Superior dimensional accuracy that makes everything else easier to install

- Superior energy performance with minimal thermal bridging

- Superior quality installed insulation (e.g.,no gaps, voids, compression, shrinkage control, settling control)

- Superior air-tight assembly

- Superior thermal storage to help buffer homes from overheating

- Superior moisture storage to buffer the home from moisture related issues

All told, Rashkin lists 17 characteristics where ICPs–done right–can be superior to traditional wood or concrete framing.

You don’t arrive there without the characteristic Michael Niemann lists as his most pronounced: persistence.