Kirk Gittings

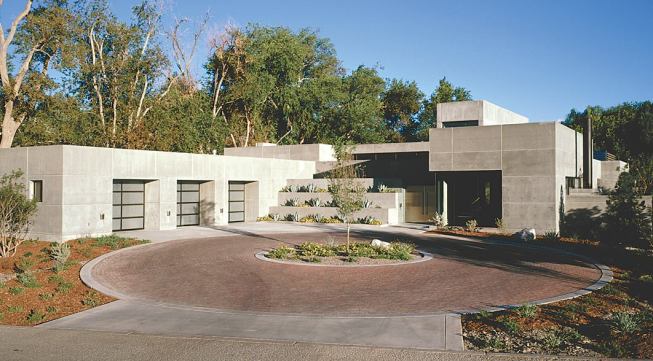

Crystalline geometry and uniform cast-in-place concrete finishes…

When a well-heeled El Paso, Texas, client presented him with the idea of building a cast-in-place concrete house, architect Jon Anderson hesitated for a moment. “I was a little leery of it,” he admits. This was not due to any fault in the material itself, but because he did not know a residential concrete contractor who could produce the quality of work the project would require. “It’s hard to get good-looking concrete in the residential realm,” says Anderson, who turned instead to an industrial subcontractor, Albuquerque, N.M.-based Cambro Construction. Not only could the company turn out first-rate architectural concrete work, but it also happened to have a 75-man crew in town—building a sewage-treatment plant.

The project still gave them a work-out. “Some of these walls are 24 feet tall,” Anderson says, “and there are no horizontal cold joints.” Exterior walls, 12 inches thick, were cast around a 3-inch layer of rigid foam insulation. In this no-redo scenario, a quality result depended on “the joinery on your forms and the cleanliness of your forms and making sure the placement and vibration is done right.” Getting the right mix, the right reveals, and the right pattern of snap ties was essential too. “We did eight on-site samples before we poured any concrete on that house.” Pouring the walls alone took 12 weeks.

Under foot is a post-tensioned concrete slab with 10 zones of hydronic heat. Where the slab was left exposed, the concrete was polished, stained, treated with an acrylic sealer, and waxed. Ceilings and furred-out interior walls are pigmented plaster with a diamond finish that looks like machined stone. “The finishes are very simple inside,” Anderson says. “The concrete comes right down and hits the floor.” Against this monolithic backdrop, accent materials stand out in bold contrast: agave plants in a stepped planter near the entry, polished stainless steel doors at the courtyard gate and entry, a 10-foot-high water wall of saw-kerfed black granite, a cherry paneled den. But none of them steals the show. In this house, concrete is the main attraction.

Project Credits

Builder: Joe Nowell, El Paso, Texas

Architect: Jon Anderson, Albuquerque, N.M.

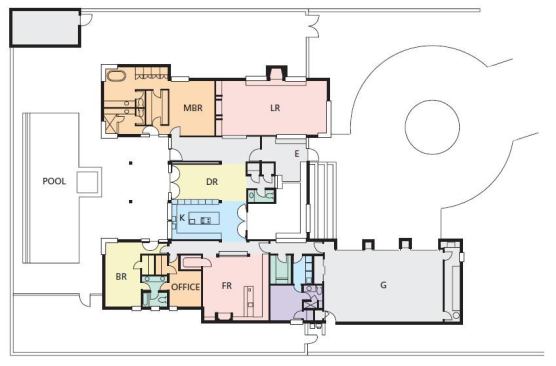

Living space: 4,600 square feet

Site: .47 acre

Construction cost: Withheld

Photographer: Kirk Gittings Resources: Bathroom plumbing fittings: Hastings; Bathroom plumbing fixtures: Kohler; Dishwasher/oven: Gaggenau; Garage doors: Wayne Dalton; Garbage disposer: In-Sink-Erator; Hardware: Medico; HVAC equipment: York; Insulation: Dow; Kitchen cabinets: Bulthaup; Kitchen plumbing fittings: Kohler; Kitchen plumbing fixtures: Hastings; Lighting fixtures: Iris; Patio doors/windows: U.S. Aluminum; Refrigerator: Sub-Zero; Security system: Elexos.