Radiant floor heating just might be the oldest luxury heating technique in history. Roman engineers, faced with the task of heating their enormous bath houses, developed their own floor heating system called the hypocaust: a floor raised on pillars over a hot furnace, creating warm floors and a toasty room.

In modern times the technology of radiant floor heating has changed, with polyester mesh electric heating mats or flexible plastic tubing replacing wood-burning furnaces. But the effect has stayed the same: luxuriously warm floors that heat the room and pamper the body.

Today the technology is growing faster than ever, fueled by advances in materials, concerns over energy costs, and homeowners’ desire for spa-like bathrooms that indulge their desire for comfortable surfaces. Owners of heated floors will notice the comforting heat at first, but, as with the sun, the floors become second-nature necessities over time, says Dan Chiles, vice president of marketing for Watts Radiant.

“Homeowners are emotional about their radiant floor,” he says. “They’d rather give up their roofs then their radiant floor.” Watts Radiant offers two different floor heating options for builders and remodelers, with different applications. Electric mats are mostly used for smaller areas and are usually used just for floor warming, rather than as a primary heating source. Because they are quick and easy to install, they are often used for remodeling. Hydronic or hot water heating, on the other hand, is often used throughout a house and can serve as the primary source of heat. Installing the pipes and related infrastructure requires more planning and time, however.

“If [homeowners] want hot water, they have to decide very early on,” says Steven Klenk, vice president of home builder Pinnacle Custom. “The construction of the home almost revolves around whether they want radiant or not.” Klenk says his firm uses both hot water and electric, adding that if the home already has a boiler servicing a baseplate, it makes economic sense to use hot water heating.

More Floors. Both electric and hydronic radiant heating have grown as fast as consumers’ interest in recent years. A Radiant Panel Association survey of manufacturers and primary importers found 2005 sales of hydronic tubing at 333 million feet, an increase of about 36 percent since 2003, though virtually flat since 2004. The survey also estimated North American electric radiant panel element sales at 6.2 million nominal square feet in 2005, a 7 percent rate of growth after sales numbers almost tripled in 2004. While growth appeared to level off last year, Larry Drake, executive director of the RPA, says it may just be the result of consolidation in the industry. “Everybody seems to agree that the industry is booming,” he says.

Much of the growth seems to come from a realization among consumers that radiant floor heating is not as expensive as it once was. Manufacturers estimate the average pre-installation cost of a bathroom electric radiant heating system, including programmable thermostat, at around $400 to $700. “Ten years ago people thought of it as something to do if you won the lottery,” says Kevin McElroy, vice president of sales for Nuheat. “Now it’s the next necessity.”

After seeing the price of the electric mats, more homeowners are choosing to install floor heating in new areas of the home. While McElroy says 80 percent of his company’s products are used in kitchens or baths, contractors and installers are putting radiant floors everywhere from foyers and galleries to basements, breezeways, garage conversions, and room additions. Some homeowners have taken to installing radiant heating under their shower floor. “Even in the kitchen, people are finding that the granite countertops are uncomfortable for their elbows,” McElroy says, “so they’re putting electric mats on a plywood base then under the granite countertop.”

Drake says that a burgeoning emphasis on green building should drive growth for all kinds of radiant floor heating. “Radiant is undoubtedly the most healthy heat system out there,” he says. With the costs of electricity, gas, and oil all rising, homeowners find the energy savings with radiant heat appealing. McElroy says that Nuheat’s electric floor mats draw only about 12 watts per square foot. “It’s a fallacy that it’ll cost a lot to run,” he says. “The whole system uses the same amount of electricity as the light bulbs in a room.” Additionally, most electric floor heating systems come with programmable thermostats, allowing the homeowner to turn on the heat for just a few hours a day.

Hydronic is Hot. While hot water radiant floor heating does not have the advantage of programmability, new technologies mean that energy savings for hydronic heating are quickly growing. In the past, most hot water heating systems were built using the staple-up method in which hydronic tubes are stapled to the underside of the subfloor, or the wet pour method in which the tubing is embedded in poured concrete. But staple-up is less efficient and requires higher water temperatures, and the wet pour method requires days or weeks of building time as well as additional framing reinforcement. New dry modular panel systems, made of aluminum or concrete in a plastic shell, for example, allow installers to quickly construct a hot water heating system that conducts heat as well as or better than a concrete slab. “The trend is to go with more dry systems,” says Lance MacNevin, manager of heating and plumbing technical services for Rehau.

The more efficient panels also allow homeowners to take advantage of high-tech condensing boilers. “The condensers are more efficient at low temperatures, so you can crank out 99 percent efficiency on a propane or gas boiler,” says Jim Bolduc, owner of Jim Bolduc Plumbing and Heating in Cumberland, Maine. Radiant floor heating systems can also be constructed to take advantage of solar or geothermal energy. “When gas and oil goes to $5 per gallon, we’re going to be putting in more efficient equipment and customers are going to want to pay for it,” Bolduc says.

A growing awareness among consumers about radiant floor heating due to publicity from home magazines and TV shows like “This Old House” means that builders and remodelers have an opportunity to upsell their clients. While the initial cost and hassle of the installation is higher, the payoff in both comfort and energy savings for the homeowner and profit for the contractor is worthwhile, installers say. “It’s labor-intensive, but it’s the most rewarding system to put in because you can get the most satisfaction from the homeowner, and you can make a lot of money from it,” Bolduc says.

This story first appeared in BUILDING PRODUCTS magazine.

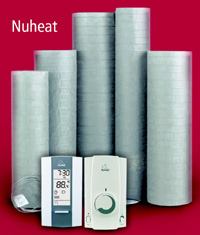

Nuheat

Constructed of thin heating wires embedded in a 1/8-inch-thick mat, this electrical radiant floor warming system is available in 110V and 220V formats and more than 60 standard mat sizes, as well as custom sizes for curves and angles. The thermostat has pre-programmed and programmable settings. 800.778.9276. www.nuheat.com

Rehau

The Raupanel radiant heating system consists of 3/8-inch Raupex cross-linked polyethylene pipe, aluminum panels, and wood return bends. The heat transfer efficiency of the aluminum panels allows for reduced water temperature, according to the manufacturer. The system’s 5/8-inch profile has minimal impact on floor height, the firm adds. 800.247.9445. www.rehau.com

Easy Heat

The Warm Tiles electric floor warming system is designed for tile, stone, and engineered wood floors. Cables can be installed in any design configuration, while pre-fabricated mats are suited for concrete slab applications, as well as for square and rectangular rooms. Thermostats include a floor sensor embedded in the mortar below the tile. 800.537.4732. www.warmtiles.com

Infloor

The InfloorBoard modular hydronic system is made of composite boards with an aluminum layer for quick heating acceleration, according to the manufacturer. Alternatively, Radiant Trak plates are installed facing each other between the joist spaces on the underside of the subfloor, keeping the heating pipe in place. 763.478.9660. www.infloor.com

Viega

ProRadiant heating systems are designed to be used with any type of floor covering. The Climate Panel radiant underlayment system, engineered for wood frame construction, is made of aluminum-backed plywood with grooves designed for Viega PEX tubing. The Snap Panel grid system is used for regular or lightweight concrete applications. 877.843.4262. www.viega-na.com

Bylin Engineered Systems

WarmGlo radiant floor heating cables are designed for tile, marble, slate, and other stone surfaces. The cables are made of an alloy heater element wrapped with 4-mil Kapton, and then encased in silicone rubber, a ground braid, and another layer of silicone rubber. 916.933.5666. www.bylinusa.com

Electro Plastics The Step Warmfloor electroplastic heating element is different from hydronic and cable heating systems because of its self-regulating semi-conductive polymer, which allows it to draw only the energy required to maintain the ideal temperature, the manufacturer says. The technology also eliminates thermal mass and expansion issues, according to the company. 877.783. 7832. www.warmfloor.com