Innovation takes collaboration. And sometimes innovation happens as an unintended consequence to a tangential project.

That’s what happened years ago when a group of scientists focused on cellulose nanocrystals were brought together by the US Forest Service, the National Science Foundation and Purdue University. They discovered a stronger, more flexible alternative to concrete. The group was recognized as a HIVE 100 Innovator in September because of the impact this innovation will have on housing.

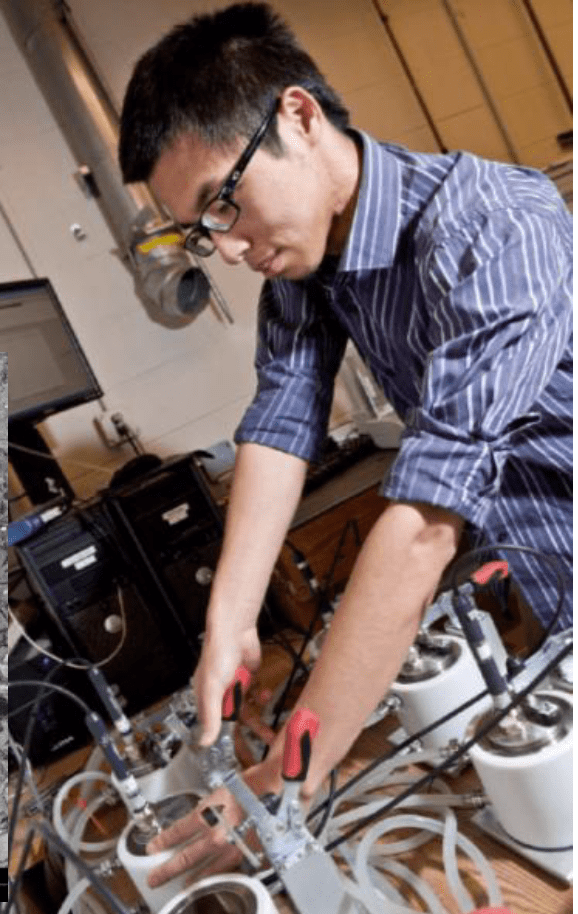

The group, established in 2010 at Purdue by Robert Moon, materials research engineer at Renewable Bioproducts Institute at Georgia Tech and materials research engineer at the U.S. Forest Service, included Jeffrey Youngblood, professor, Purdue University’s School of Materials Engineering; Jason Weiss, director, Kiewit Center for Infrastructure and Transportation Research at Oregon State University; Pablo Zavattieri, associate professor of civil engineering, Purdue University; and Yizheng Cao, Purdue Ph.D. student and lead author of the group’s findings, and now a scientist at Albany Molecular Research.

“In the beginning, the U.S. Forest Service wanted to advance the exposure of and research with cellulose nanocrystals, with the ultimate goal of using such materials in consumer products,” Moon says. “They started partnering with institutions. Purdue was one of the only ones that embraced it and invited me to come and lead this initiative. I started interacting with faculty at Purdue to get them excited about cellulose nanocrystals. Jason, Jeff, and Pablo were all very interested and saw the potential for them.”

The group formed a think tank of how to use cellulose nanomaterials, and that’s when Zavattieri came up with the idea of adding them to cement. The team members had ideas but needed funding, so they created a proposal and sent it to the National Science Foundation.

The innovation leaned heavily on each of their strengths and past experiences. “Each one of us had a different facet and brought a different perspective on this project,” Moon says.

The group proved that the use of cellulose nanocrystals can increase the flexural strength of concrete by 30%. Their discovery outperforms alternatives in strength, impact resistance, and flexibility.

“It’s well known that concrete is the second most used material by mankind behind water,” Youngblood explains. “To prepare cement, you use limestone in a giant furnace, and the furnace produces a lot of CO2. Which means that there is a lot of impact in the environment. If you could improve the strength and use less cement, then you are reducing the impact on the environment. If you have 30% stronger concrete, then you may be able to use 30% less and move the needle that far on the impact.”

The group also notes that cement contributes to 5% of the world’s CO2, so any improvement would have a massive and lasting impact on the health of the environment.

Purdue University

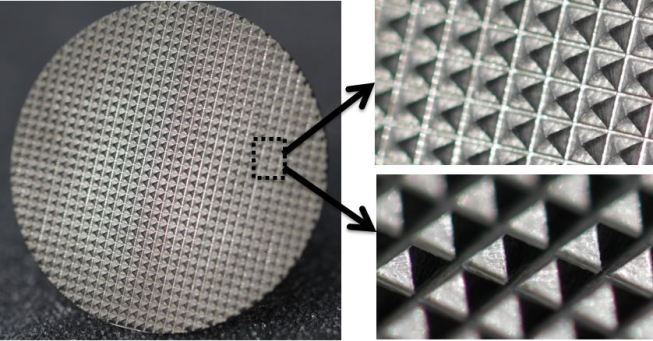

Understanding concrete at a smaller scale with microstructural images

In addition to compression strength, the group’s findings also give the cement flexural strength. Any improvement in flexural strength is monumental. This new breed could improve concrete enough to help prevent structural bending cracks.

“The typical way to increase the flexural capacity is to make it deeper, which would be adding more material,” Weiss says. “With the addition of the nanomaterials, you can make thinner sections but with better performance. This is a natural material that is very easy to work with.”

Cao explains that before their work, scientists tried to accomplish the same results but their materials were not biodegradable and were too expensive. “CNC [cellulose nanocrystals] can be extracted from trees and plants so it’s a natural material. It’s greener. It’s a better alternative and the only option that can reinforce at a nanoscale.”

Weiss explains that thin sheet cements have always been a great product in building. Years ago, the small fiber of choice was asbestos and it was widely used because of its slim attributes. Now we are looking at printing thinner materials. Not only thinner, but with higher performance.

Purdue University

Looking at how cellulose nanocrystals alter behavior of cement

The group’s innovation has a wide variety of building applications. It will not replace the need for the mass and strength in foundations, but it could easily be found in a floor slab. “The advantage for this type of approach is to increase the strength to 30% or even up to 50%,” Weiss says. “And that would decrease the thinness and save an inch or two per floor with similar performance. We then have the ability to look at concrete countertops that are stronger. Cement-based extruded tiles that are stronger. And gypsum.”

Weiss discussed how the recognition from HIVE will further enhance this and other innovations. The group received funding from the National Science Foundation but still has work to do to get the product commercialized.

“Eighteen years is a pretty reasonable timeline to bring something from science to implementation in the civil world. We are going from research to potential use in a concrete slab that is a much shorter time frame than that—a third or half,” Weiss says. “The way that comes about is through the process that comes about here, with a multidisciplinary team that works on how to move the science to application and it gets picked up by others. HIVE is a different and interdisciplinary team that can say this is what we need to move it from where it’s at to ubiquitous use. Move it to not a newsworthy event but something that is an everyday use. HIVE short circuits the time for innovation.”

Moon says that even though they have improved the strength by 30%, this is just the beginning. “The neat thing that the cellulose nanocrystal additions to cements resulted in were new mechanisms for property improvements. It was a real paradigm shift. We now have a new way to influence the reactions in the cement as it sets so it gives us new opportunities to get higher and improved strengths,” he explains. “With further exploration, we are ready to further understand the mechanims, optimize and achieve even more property improvements.”